Enhancing Item Advancement with Advanced Plastic Injection Molding Solutions

The Future of Plastic Shot Molding: Developments and trends to Enjoy

As the plastic injection molding sector evolves, a number of key trends are emerging that guarantee to reshape its landscape. Automation and wise production methods are readied to enhance performance, while the shift towards lasting materials shows an expanding ecological awareness. Additionally, advancements in 3D printing are leading the way for unmatched layout versatility. Nevertheless, these advancements likewise yield difficulties that call for mindful factor to consider. Recognizing exactly how these components will engage and influence future methods is essential for stakeholders looking to navigate this transformative duration successfully.

Automation and Smart Production

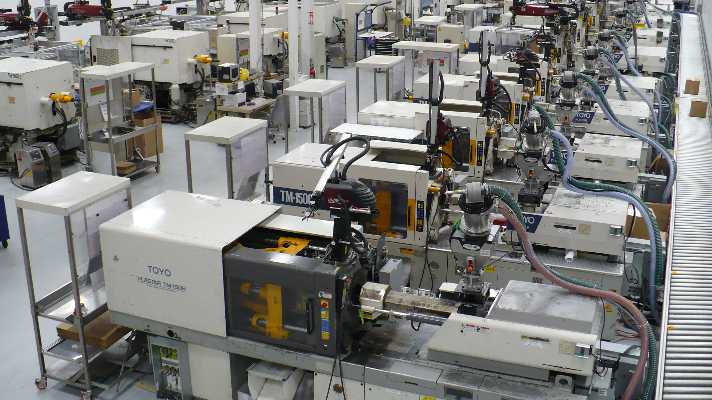

As the plastic injection molding sector advances, automation and clever manufacturing are taking spotlight, changing manufacturing procedures - Plastic Injection Molding. The integration of advanced modern technologies such as robotics, IoT (Web of Things), and man-made intelligence is making it possible for producers to boost efficiency, decrease functional prices, and boost product top quality. Automated systems improve workflows, reducing hand-operated treatment and raising throughput, which is essential in satisfying the increasing demand for fast production cycles

Smart producing modern technologies assist in real-time surveillance and data evaluation, allowing firms to optimize device performance and forecast maintenance demands. This aggressive strategy not only reduces downtime but also prolongs the life expectancy of tools. The use of joint robotics, or cobots, improves the versatility of manufacturing lines, allowing makers and employees to run side by side safely and successfully.

The adoption of automation in plastic injection molding is not merely a trend however a tactical essential for organizations intending to continue to be competitive in a global market. By using these innovations, suppliers can attain greater precision, reduce waste, and adjust swiftly to transforming customer demands, positioning themselves for sustainable growth in an increasingly automated future.

Sustainable Products and Practices

The push in the direction of automation and wise manufacturing has actually paved the means for a higher emphasis on lasting materials and methods within the plastic shot molding sector. Firms are increasingly looking for environmentally friendly alternatives to standard petroleum-based plastics, bring about the adoption of recycled and bio-based materials. These lasting materials not just decrease environmental influence but additionally straighten with consumer need for greener products.

Moreover, partnership between makers, material providers, and ecological organizations is fostering innovation in the development of lasting materials that satisfy efficiency requirements without endangering top quality. As policies around plastic use become more stringent, the sector is positioned to adjust by welcoming these sustainable techniques, making sure long-lasting viability and reducing reliance on non-renewable sources. The combination of sustainability right into plastic injection molding is not just a trend; it is coming to be a crucial element of corporate responsibility and functional quality.

Developments in 3D Printing

Current improvements in 3D printing technology are dramatically transforming the landscape of plastic injection molding. Once tough or impossible to attain with conventional approaches, the assimilation of additive production processes allows for the rapid prototyping of intricate geometries that were. This capability not just speeds up product development cycles but likewise lowers material waste, straightening with the growing need for sustainable manufacturing techniques

Furthermore, the appearance of crossbreed manufacturing methods, which linked here incorporate 3D printing and injection molding, provides producers the ability to create elaborate styles while maintaining the performance of mass production. This strategy makes it possible for the manufacturing of customized components customized to details consumer needs without compromising the rate and scalability that injection molding provides.

Additionally, advancements in materials, such as high-performance polymers and compounds especially made for 3D printing, are enhancing the functional abilities of published parts. These materials can endure higher stress and display enhanced thermal properties, making them appropriate for even more demanding applications.

As 3D printing proceeds to develop, its assimilation right into plastic injection molding procedures assures to improve productivity, reduce prices, and foster development in item layout, placing producers to better fulfill the difficulties of a competitive market.

Information Analytics and IoT Integration

Data check this site out analytics and the assimilation of the Internet of Points (IoT) are changing plastic shot molding by offering manufacturers with extraordinary insights into their procedures. my company By leveraging real-time information collected from interconnected machines and sensors, suppliers can keep track of performance metrics, identify inadequacies, and enhance production processes. This data-driven method helps with anticipating upkeep, reducing downtime and expanding tools life-span.

Furthermore, IoT combination permits improved quality assurance. By continually tracking variables such as temperature, cycle, and pressure times, producers can swiftly discover inconsistencies from established parameters and make adjustments in actual time. This not only boosts product consistency however also reduces waste and scrap rates.

The blend of data analytics and IoT modern technologies likewise empowers producers to adopt even more nimble manufacturing methods. With access to detailed information analytics, companies can react to market needs with better flexibility, changing manufacturing schedules and configurations as needed. This flexibility is important in a swiftly changing production landscape.

Modification and Design Flexibility

How can personalization and design versatility improve the competitiveness of plastic shot molding? Personalization allows suppliers to fulfill details customer needs, fitting one-of-a-kind dimensions, shapes, and functionalities that typical products may not satisfy.

Innovations in design modern technologies, such as computer-aided style (CAD) and rapid prototyping, additional reinforce this trend. These tools enable developers to create intricate patterns and complex geometries, which can be perfectly integrated into the manufacturing procedure. As an outcome, producers can respond swiftly to changing consumer preferences and market needs.

Moreover, the application of modular tooling systems enhances layout adaptability, permitting quicker modifications between different item layouts without considerable downtime. This flexibility can result in lowered preparations and lower manufacturing expenses, making business much more agile and competitive. Eventually, welcoming modification and style versatility in plastic shot molding not just raises product offerings however also reinforces market positioning in an ever-evolving landscape.

Final Thought

The future of plastic injection molding is characterized by substantial innovations in automation, sustainable methods, and ingenious products. Modification with modular tooling and fast prototyping will make it possible for makers to stay receptive and competitive to the vibrant demands of the market.

The future of plastic shot molding is defined by considerable advancements in automation, lasting practices, and ingenious materials.